AUMUND Asia Ltd, located in Hong Kong China, is acting in the Asia Pacific Area and sells AUMUND, SCHADE and SAMSON equipment in all kinds of key industries such as Cement, Mining & Minerals, Chemical and Fertilizer Industry, Ports & Terminals and many others more. Synergies within the AUMUND Group of companies consistently lead to successful outcomes: In May 2020 AUMUND Hong Kong won an order from PT Asahimas Chemical, Java/Indonesia, for the New Generation of STORMAJOR®. The project was technically supported by SAMSON Materials Handling Ltd/UK leading product company in the AUMUND Group for mobile bulk handling solutions. The pre-assembly of the STORMAJOR® takes place in the workshops of AUMUND Foerdertechnik GmbH, Rheinberg/Germany. The delivery is planned for December 2020.

New Generation STORMAJOR® with Outloading Boom

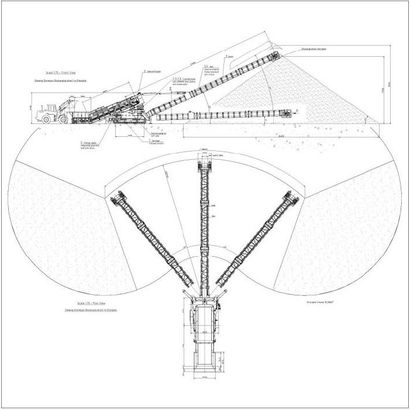

(drawing and pre-assembly AUMUND Foerdertechnik GmbH)

The new designed STORMAJOR® is the combination of a Mobile SAMSON Material Feeder and an Outloading Boom, both mounted on the same chassis. The diverse options for stockpiling and loading offered by the STORMAJOR®were the compelling factor in the order from PT Asahimas Chemical, a company which operates several chemical production plants in Cilegon in Banten Province, Java, Indonesia. In 2018 it built its own power plant, where the first New Generation STORMAJOR® will operate, serving an important purpose in minimising spontaneous combustion of coal by stockpiling the coal externally and bringing it back inside once it has cooled down.

Challenge: Danger of smouldering coal fires caused by glowing nests

PT Asahimas Chemical is concerned about embedded hot bodies, which occur frequently causing the coal to catch fire in covered storage areas of the power plant. Currently the glowing nests are removed with diggers from the stockpiled coal and transferred to an external storage area about 50 m away by dump trucks, where the coal is left to cool down before being taken back into the covered storage areas using the same diggers and dump trucks.

The new generation of STORMAJOR®both simplifies and speeds up the process of moving the coal. The machine is placed centrally between the stockpile and the covered storage area, from where it can both receive the coal from the diggers and stockpile it outside the covered storage area via the STORMAJOR®Outloading Boom. When the coal has cooled down the STORMAJOR® turns in the opposite direction, receiving the coal back from the digger and transporting it back into the covered storage area. This new process of utilising the STORMAJOR® also decreases the amount of times the coal has to be handled, which reduces the material degradation keeping the quality of the coal intact, whilst operating at 300 tonnes per hour. The STORMAJOR®therefore increases the efficiency and productivity of the complete process cycle.

PT Asahimas Chemical selected a 450 Series STORMAJOR®, which is the medium-sized model, for its operation in Indonesia. The bucket capacity for material discharge is approximately 4.5 t and a conveying length of 11.5 m.The Outloading Boom is 27 m long, has a luffing range from 2 to 30 degrees and a slewing range of 80 degrees (40 degrees in each direction). ThisSTORMAJOR® forms stockpiles of up to 11.75 m in height